Anyway, so next week I am going to Vegas for vacation 8-), and then when it warms up a little more, like in a month, I am going to go to the ocean for a few days, and I am going to just sit there and stare at it for hours on end, and see what happens.

Ok, back to the Brutus 10 clone build. So, I decided to climb on the structure and jump around to see what happened. What happened? I think nothing, but at the time I think I sort of imagined that it was a little bendy, so I added more supports. The model has a single vertical support, so as usual I went above and beyond that. Overkill? Probably. Not much to say here, I will let the pictures speak for themselves. At this point, I am getting pretty good at welding. I still lay a stinker every once in a while, but they are few and far between.

So now it was time to add some wheels to the rig. I went with casters that can handle 240 pounds each. So 4 would handle 960 pounds. Again, overkill. The kegs weigh about 30 pounds each when empty. So that's 90 pounds. Under worst case scenario conditions, say I have all 3 filled to the brim with water, that's another 15 (gals) x 8 (pounds/per) x 3 (kegs) = 360 pounds. So now we are up to 450. Factor in the steel structure, and that's another probably 100 pounds. So 550, plus add hoses, connectors, pumps, buttons, lids, plumbing, etc... I could see it being 700 pounds. So 960 pounds of support from the casters should be ample. Also, I went with locking casters so the damn thing wouldn't roll away with my beer in it. So the next challenge was to mount them. I had this idea swimming around in my head as to how to do it, and when I read a a post on homebrewtalk.com about someone doing it the same way, I figured it would work well. The plan, Take some steel, drill a hole in it, and weld a nut on top of the hole, so the threaded stem from the caster can screw into that.

Is this amount of welding overkill? You decide. Do I know any better? nope. I don't recall getting a memo, or seeing any instructions anywhere on how to weld a nut to a piece of steel. Better safe then sorry I suppose.

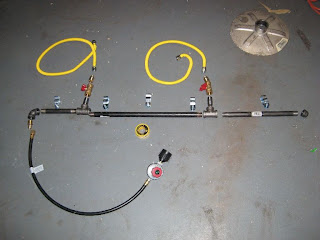

So then I moved in to plumbing. Some people build these things where their propane or natural gas travels through one of the structural beams. I have little faith in my welding skills, so trying to weld something that can withstand internal pressure of the gas seemed like a bad plan, so from the start, I planned on having external plumbing, and standard black steel pipe seems to be the most widely accepted solution. So a trip to the hardware store later I had all these pieces.

So when assembled it looks like this.

Next, I had to mount the plumbing system to the structure. I located some relatively thick pipe hangers and welded them in place.

By the way, here is what happens when you try to weld really thin stuff, it essentially just burns away.

All in place, nice! It is really starting to shape up. Still a lot of work to do though.